IC Substrates

Ceramic Substrates

High Density PCBs

Packaging Solutions

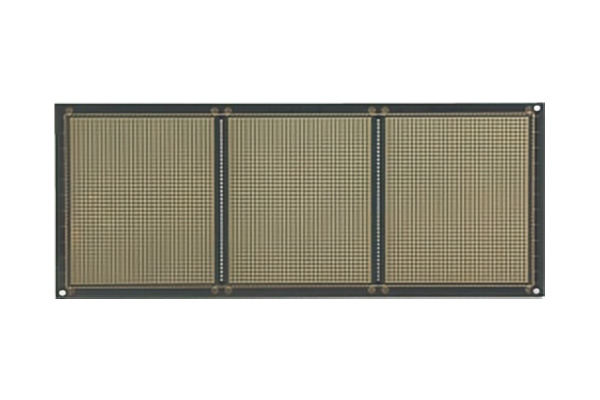

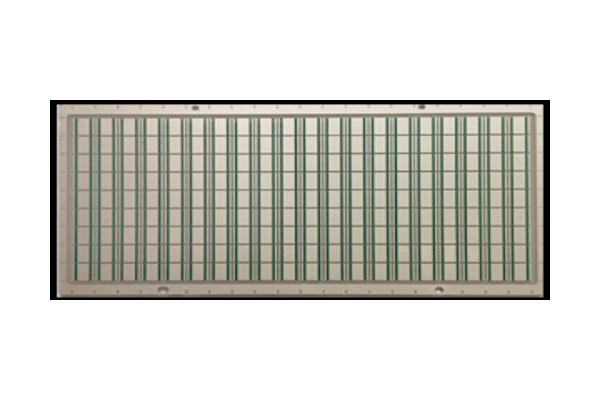

• Application: 800G Optical communication

• Layers: 12L

• Min hole size: 60μm

• Core material: ABF low Dk/Df

• L/S: 15/15μm

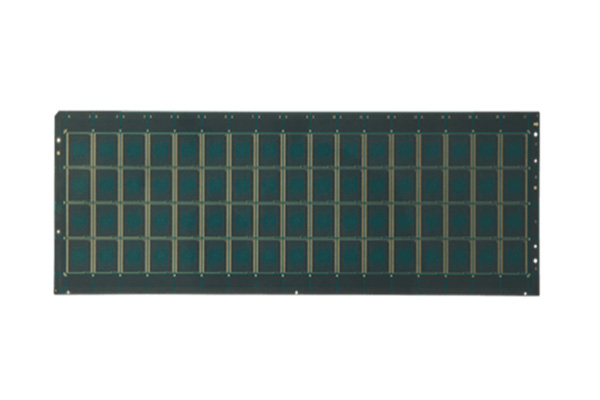

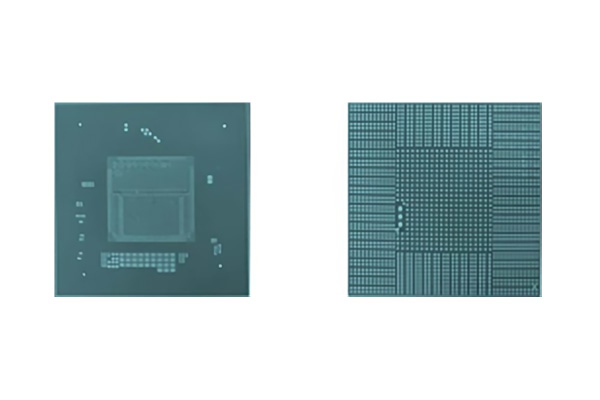

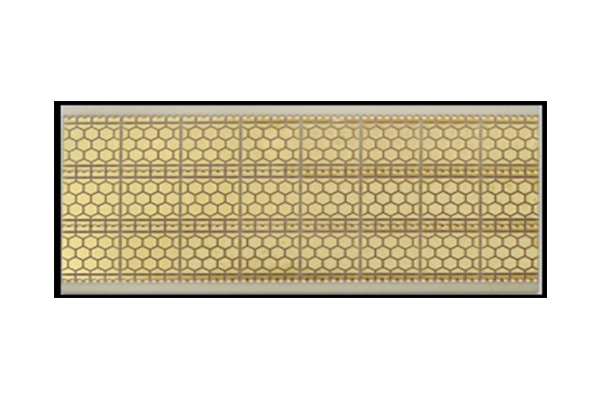

• Application: GPU

• Layers: 10L

• Min hole size: 60μm

• Core material: ABF low Dk/Df

• L/S: 15/15μm

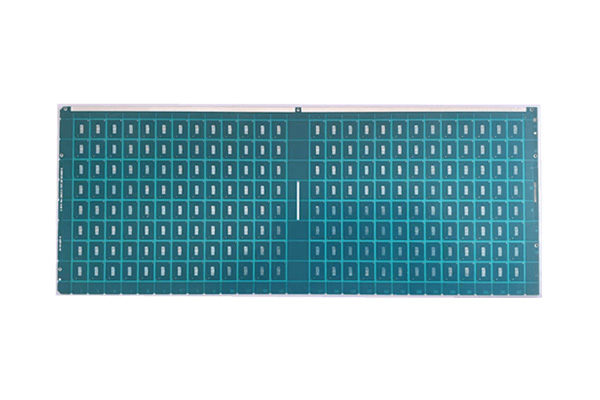

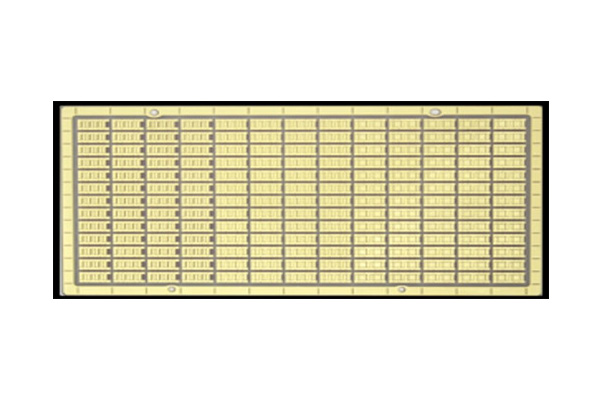

• Product type: FCCSP for memory

• Layers: 4L

• Min. hole size: 80μm

• Core material: ultra low CTE and high TG

• Min. L/S: 20/20μm

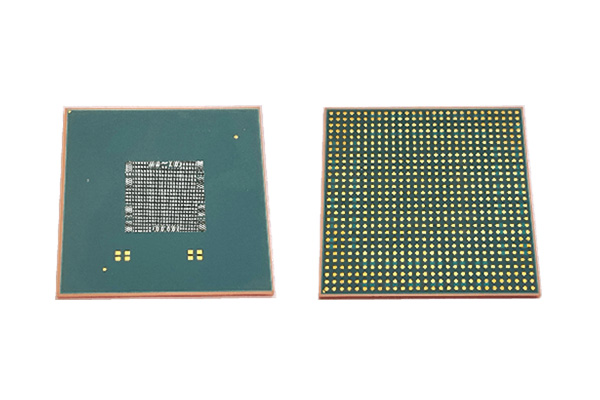

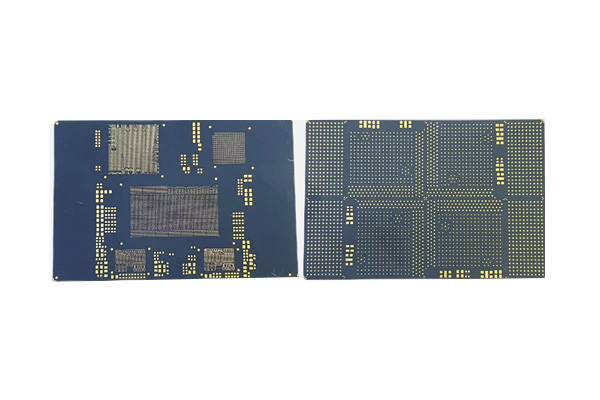

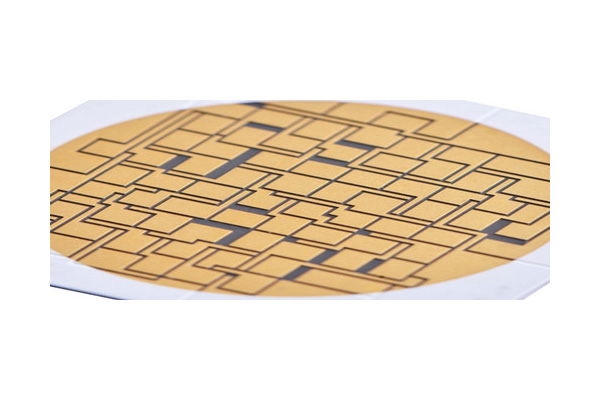

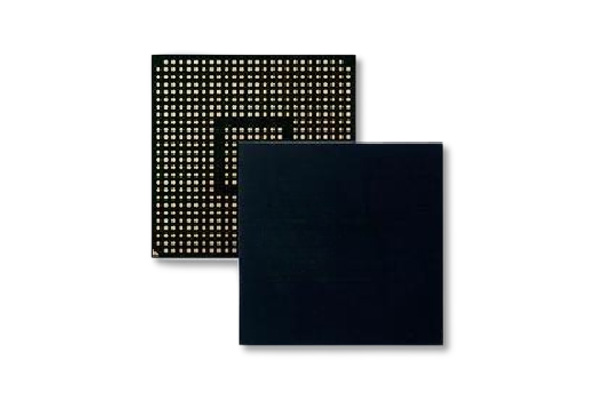

• Product type: FCBGA for CUP

• Layers: 14L

• Min hole size: 60μm

• Core material: ABF+E705G

• Min. L/S: 12/12μm

• Application: High performance computing

• Layers: 8L

• Min hole size: 80μm

• Core material: BT low CTE

• L/S: 20/20μm

• Product type: Micro-LED

• Layers: 4L

• Unit size: 8.45x8.45mm

• Core material: HL832NS

• Solder mask: PSR-4000ME

• Min. L/S: 25/25μm

• High thermal conductivity

• Excellent insulation

• Very low coefficient of expansion

• Low dielectric constant and dielectric loss

• Chemical resistance

• High thermal conductivity

• Excellent insulation

• Very low coefficient of expansion

• Low dielectric constant and dielectric loss

• Chemical resistance

• Ultra-high thermal conductivity (170-220W/m.K)

• Excellent insulation

• Extremely low expansion coefficient

• Low dielectric constant and dielectric loss

• Resistance to chemical corrosion

• High thermal conductivity

• Excellent insulation

• Very low coefficient of expansion

• Low dielectric constant and dielectric loss

• Chemical resistance

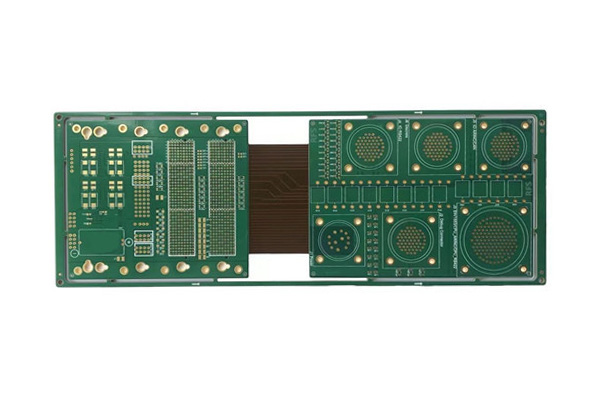

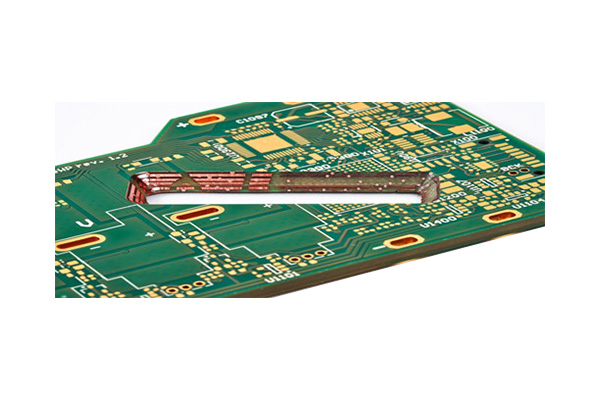

• 14L, rigid-flex

• Air Gap design

• applied in the field of

• large medical equipment

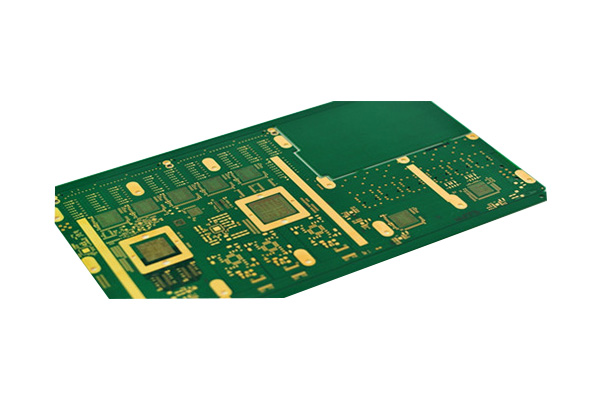

• 18L rigid-flex

• 2(rigid)+14(flex)+2(rigid)

• Air Gap design

• Applied in the field of high-end communication

• The base copper can reach 3OZ

• And the finished copper thickness can reach 12OZ

• It is widely used in microwave, aerospace

• Satellite communication

• Network base station

• Hybrid integrated circuit

• Power high-power circuit and other high-tech fields

• Up to 32 layers

• And the structure can realize any layer interconnection

• Which is widely used in mobile phones

• Digital cameras, notebook

• Automotive electronics and other digital products

• Small in size and light in weight

• Low power consumption

• Good heat dissipation effect

• High system integration

• Low production cost and short market launch cycle

• Small in size and light in weight

• Good heat dissipation performance

• Excellent electrical performance

• Lower cost

• High reliability

• High-density HDI fine pitch substrate

• Advanced bonding process

• Mature technology and low cost

• High wiring density

• Support for multi-chip applications

• Support antenna applications within the package

• High reliability

• High-density interconnection

• Excellent heat dissipation performance

• Low inductance and resistance

• High reliability

• Miniaturized design

Reach out to us via chat, phone, or our simple contact form.

Get a FREE Quote Today

Our business scope includes IC substrate design and simulation, IC substrate manufacturing, IC packaging and testing, as well as comprehensive hardware assembly services(PCB & PCBA).