SpaceX Plans Texas-Based Chip Packaging Facility with FOPLP Technology

Jun 07,2025

June 2025 – Texas, USA — SpaceX is making strategic moves toward semiconductor vertical integration by preparing to enter the chip packaging sector. While the company does not yet fabricate its own semiconductor chips, it is reportedly planning to build a state-of-the-art facility in Texas focused on fan-out panel-level packaging (FOPLP) — an advanced technology well-suited for aerospace and satellite systems.

At present, SpaceX relies heavily on external partners for chip packaging. However, with increasing demand from its Starlink satellite network and government contracts, the company is actively pursuing greater self-reliance in semiconductor production and packaging.

Strengthening Vertical Integration

Last year, SpaceX opened the largest printed circuit board (PCB) manufacturing plant in the United States in Bastrop, Texas. This factory is already a major supplier of PCBs for Starlink. Now, with FOPLP capability in the pipeline, the company is positioning itself to take the next logical step — integrating chip packaging into its vertically aligned satellite production workflow.

FOPLP, which involves processes like copper plating, laser direct imaging, and semi-additive techniques, shares significant overlap with PCB manufacturing — allowing for greater synergy and streamlined operations.

Supporting U.S. Semiconductor Independence

SpaceX’s push aligns with national efforts to strengthen onshore semiconductor capacity and reduce dependence on foreign supply chains. The move also enhances security for defense-related technologies, as packaging chips domestically reduces the risk of supply chain interference or hardware tampering.

With over 7,600 Starlink satellites in orbit and plans to launch 32,000 more for full global coverage, building mission-critical components in the U.S. is both a strategic and operational necessity.

Industry-Wide Momentum Toward Onshore Packaging

SpaceX’s expansion is part of a broader trend. Leading U.S. semiconductor players are ramping up investment in advanced packaging:

A major chip manufacturer is building a $3.5 billion 3D chip packaging plant in New Mexico.

Another industry leader has committed to a $42 billion U.S. expansion, including advanced packaging facilities.

A New York-based fab recently announced $575 million in packaging and photonics upgrades, followed by an additional $16 billion investment in domestic semiconductor capabilities.

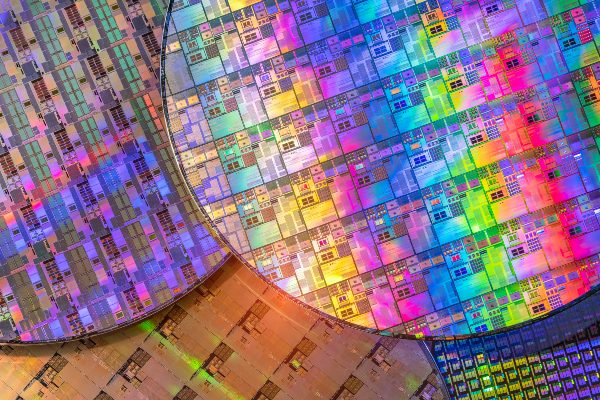

While advanced packaging plants may not garner the attention of high-end chip foundries, they play an equally vital role. They are the final step in transforming silicon wafers into functional components ready for integration into high-performance systems like satellites, servers, and AI devices.

Conclusion

SpaceX’s foray into FOPLP and chip packaging is a strategic evolution aimed at enhancing operational agility, reducing cost, and securing its supply chain. As the aerospace and satellite sectors demand ever-higher performance and reliability, building a vertically integrated chip ecosystem on American soil offers long-term resilience and global competitive advantage.